Particle kuomarara ndechimwe chezviratidzo zvemhando iyo kambani yese yekudyisa inobhadhara zvakanyanya.Muchikafu chezvipfuyo nehuku, kuoma kwakanyanya kunokonzeresa kusanzwa zvakanaka, kuderedza kudya, uye kutokonzera maronda emukanwa munguruve dzinoyamwisa.Zvisinei, kana kuoma kwakaderera, hupfu hwehupfu huchawedzera.Kudzikira kuomarara kwehombe, kunyanya yepakati uye hombe yenguruve uye yepakati duck pellet huku yekudya kunokonzeresa husingafadzi zvinhu zvakaita semafidhi grading.Nzira yekuita sei kuti kuoma kwekudya kunosangana nemhando dzemhando?Kuoma kwechigadzirwa chekudya, pamusoro pekugadziriswa kwefodya yefodya, kugadzirwa kwechikafu Iyo tekinoroji yekugadzira ine mhedzisiro yakakosha pakuoma kwepellet feed.

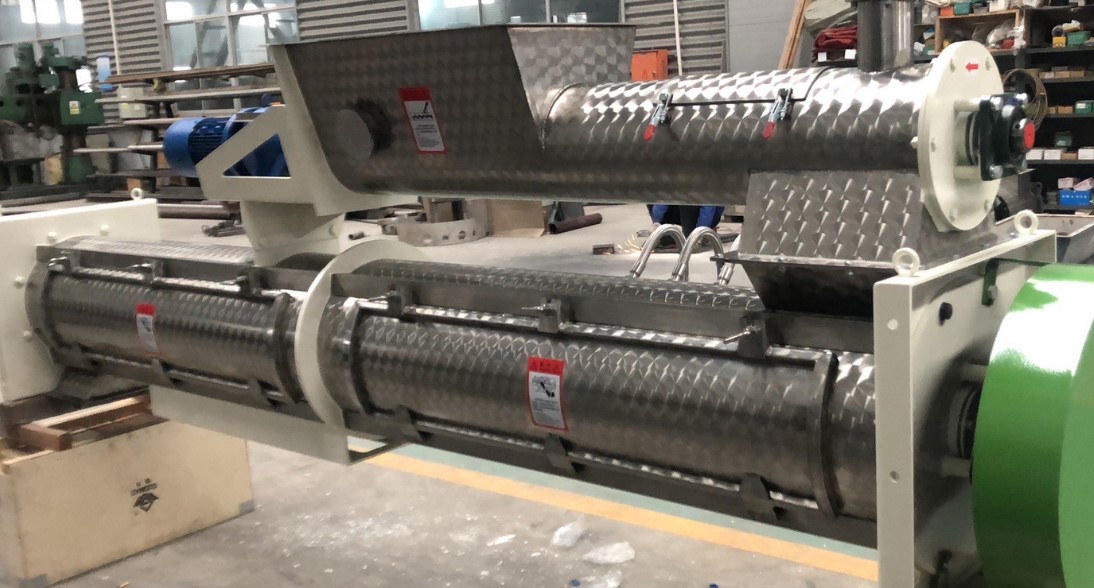

1. Pesvedzero yekukuya maitiro pakuomarara kwechidimbu.

Chinhu chinotora basa rekusimba mukuoma kwechidimbu mukukuya ndiko kukura kwechikamu chezvakagadzirwa: Kazhinji kutaura, iyo yakatsetseka saizi yekukuya yezvigadzirwa, zviri nyore kuti starch iite gelatinize panguva yekugadzirisa. nzira, uye yakasimba yekubatana kwekuita mumapellets.Kunyanya kuoma kutyora, kunowedzera kuoma.Mukugadzirwa chaiko, iyo inopwanya saizi inodiwa inofanirwa kugadziridzwa zvinoenderana nekugadzirwa kwemhuka dzakasiyana uye saizi yeinofa mhete.

2. Mhedzisiro yekupuffing process pane particle hardness

Kuburikidza nekuputira kurapa kwezvinhu zvakabikwa, chepfu mumidziyo inogona kubviswa, mabhakitiriya anogona kuurayiwa, zvinhu zvinokuvadza zvinogona kubviswa, mapuroteni ari muzvigadzirwa zvinogona kubviswa, uye starch inogona kuzara gelatinized.Parizvino, zvinhu zvakazvitutumadza zvinonyanya kushandiswa mukugadzira chikafu chenguruve chinoyamwa chepamusoro-soro uye chikafu chakakosha chemvura.Nokuda kwezvigadzirwa zvemvura zvakakosha, mushure mokunge zvinhu zvakasvibiswa zvakasvibiswa, chiyero che starch gelatinization chinowedzera uye kuoma kwezvikamu zvakaumbwa zvinowedzerawo, izvo zvinobatsira kuvandudza kugadzikana kwezvikamu mumvura.Pakudya kwenguruve inoyamwa, zvimedu zvinodiwa kuti zvive crispy uye kwete zvakanyanya kuoma, izvo zvinobatsira pakudyisa nguruve inoyamwa.Zvisinei, nekuda kwehupamhi hwestarch gelatinization muhutu hunoyamwa nguruve pellets, kuoma kwemafuro ekudya kwakakurawo.

3. Wedzera kukanganiswa kwemaitiro ejekiseni remafuta pane kuoma kwekudya.

Iko kusanganiswa kwezvinhu zvakasvibirira kunogona kuvandudza kuwirirana kweakasiyana particle saizi zvikamu, izvo zvinobatsira kuchengetedza kuomarara kwechikamu kunoenderana nekuvandudza kunaka kwechigadzirwa.Mukugadzirwa kwekudya kwepellet yakaoma, kuwedzera 1% kusvika 2% mwando mumusanganisi kuchabatsira kuvandudza kugadzikana uye kuoma kwepellet feed.Zvisinei, kuwedzera kwehunyoro kunounza migumisiro yakaipa pakuoma uye kutonhora kwezvikamu.Izvo zvakare hazvibatsiri kuchengetedza chigadzirwa.Mukugadzirwa kwemvura yepellet feed, inosvika 20% kusvika 30% mwando inogona kuwedzerwa kuhupfu.Zviri nyore kuwedzera nezve 10% mwando panguva yekusanganiswa pane panguva yekugadzirisa.Iwo magranules akaumbwa kubva kune yakakwira-unyoro-unyoro zvinhu ane kuomarara kwakaderera, akanyorova uye akapfava, uye ane kunaka kunonaka.Rudzi urwu rwemvura yepellet feed inogona kushandiswa mumabhizinesi makuru ekupfuya.Wet pellets anowanzo kunetsa kuchengeta uye anowanzo kudiwa kupihwa chikafu nekukurumidza mushure mekugadzirwa.Kuwedzera oiri panguva yekusanganisa maitiro inowanzoshandiswa mafuta ekuwedzera maitiro mumashopu ekugadzira chikafu.Kuwedzera 1% kusvika 2% yegirizi haina mhedzisiro yekudzikisa kuoma kwezvikamu, nepo kuwedzera 3% kusvika 4% yegirizi kunogona kuderedza zvakanyanya kuoma kwezvikamu.

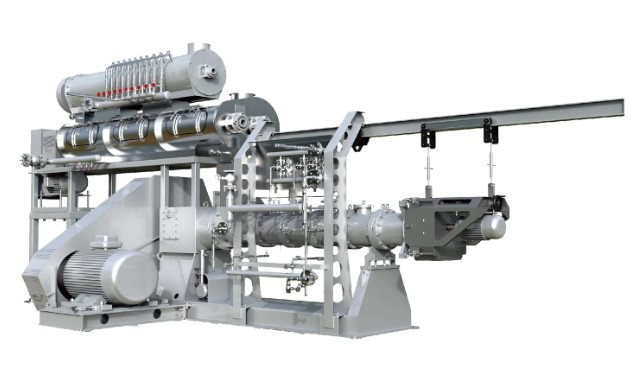

4. Mhedzisiro yemhepo inogadzirisa pane kuoma kwechidimbu.

Steam conditioning inzira yakakosha mukugadziriswa kwepellet feed, uye mamiriro ekugadzirisa anokanganisa zvakananga chimiro chemukati uye chimiro chemhando yepellets.Steam mhando uye nguva yekumisikidza zvinhu zviviri zvakakosha zvinokanganisa maitiro ekugadzirisa.Yepamusoro-soro yakaoma uye yakasvibiswa steam inogona kupa kupisa kwakawanda kuwedzera kutonhora kwezvinhu uye gelatinize starch.Iyo yakareba nguva yekumisikidza, inowedzera dhigirii ye starch gelatinization.Iyo yakakwirira kukosha, iyo denser chimiro chechidimbu mushure mekugadzira, zviri nani kugadzikana, uye kukura kuoma.Zvekudya hove, maviri-layer kana akawanda-layer jackets anowanzo shandiswa kugadzirisa kuwedzera tembiricha yekumisikidza uye kuwedzera nguva yekumisikidza.Zvinonyanya kubatsira pakuvandudza kugadzikana kwehove dzekudya kwehove mumvura, uye kuoma kwezvikamu kunowedzerawo maererano.

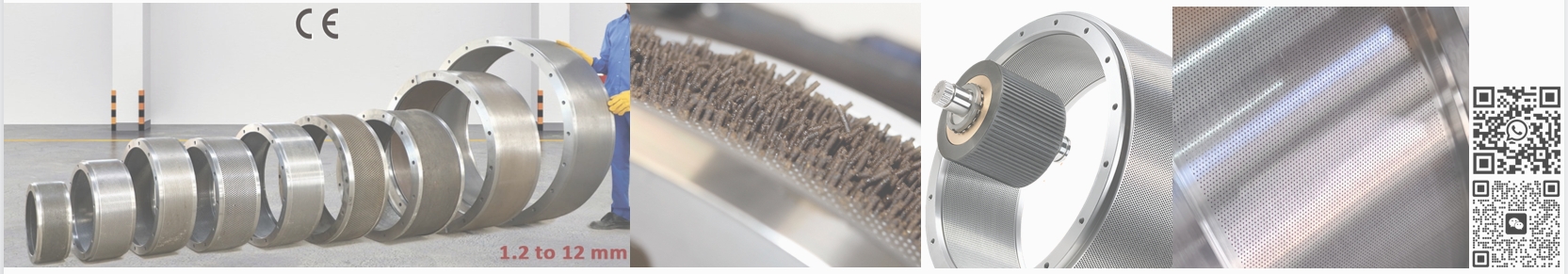

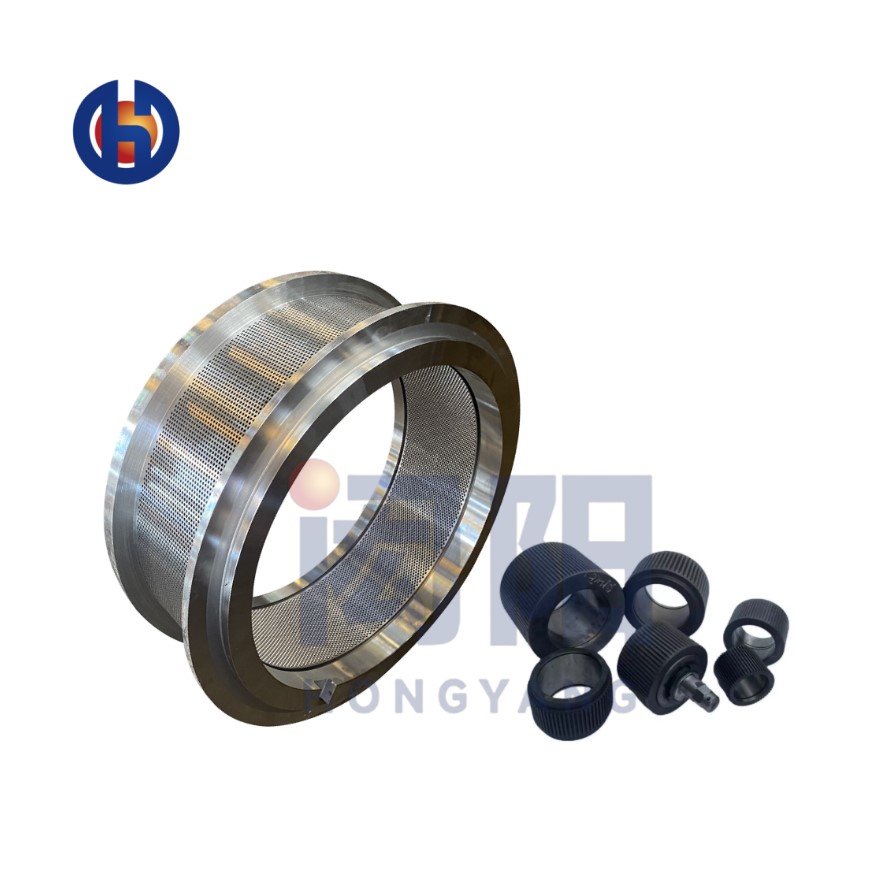

5. Mhedzisiro yemhete inofa pane kuomarara kwechidimbu.

Technical parameters senge aperture uye compression ratio yemhete inofa yefeed pellet mill inokanganisa kuoma kwema pellets.Hukukutu hwema pellets anoumbwa nering anofa neaperture yakafanana asi mareshiyo akasiyana ekudzvanyirira anowedzera zvakanyanya sezvo reshiyo yekumanikidza inowedzera.Kusarudza yakakodzera compression reshiyo mhete kufa kunogona kuburitsa zvimedu zvekuoma kwakakodzera.Kureba kwezvimedu kune zvakakosha pamusoro pekumanikidzika-kutakura simba rezvikamu.Kune zvidimbu zvedhayamita imwe chete, kana zvimedu zvisina kukanganisa, kureba kwechidimbu, kunowedzera kuoma kwakayerwa.Kugadzirisa nzvimbo yekucheka kuti ichengetedze hurefu hwakakodzera hwechidimbu hunogona kuchengetedza kuoma kwezvimedu zvakanyatsoenderana.Iyo particle dhayamita uye muchinjika-chikamu chimiro zvakare zvine imwe mhedzisiro pakuoma kwechidimbu.Mukuwedzera, zvinhu zvemhete inofa inewo imwe mhedzisiro pakuonekwa kwemhando uye kuoma kwepellets.Pane misiyano iri pachena pakati pekudya kwepellet inogadzirwa nesimbi yakajairwa mhete inofa uye simbi isina tsvina inofa.

6. Kufurira kwepost-spraying process pane particle hardness.

Kuti uwedzere nguva yekuchengetedza yezvigadzirwa zvekudya uye kugadzirisa kunaka kwechigadzirwa mukati meimwe nguva yenguva, kuomeswa kwakakodzera uye kutonhora kugadzirisa kwezvimedu zvekudya kunodiwa.Muyedzo yekuyera kuoma kwezvikamu, nekuyera kuoma kwezvikamu zvechigadzirwa chimwe chete kakawanda nenguva dzakasiyana dzekutonhodza, zvakaonekwa kuti zvimedu zvine kuomarara kwakaderera hazvikanganisike zvakanyanya nenguva yekutonhora, nepo zvimedu zvine kuoma kwakakura. kuwedzera nenguva yekutonhora.Sezvo nguva inowedzera, kuoma kwechidimbu kunoderera.Izvi zvinogona kunge zviri nekuti sezvo mvura iri mukati mezvimedu inorasika, brittleness yezvikamu zvinowedzera, zvichikanganisa kuoma kwechikamu.Panguva imwecheteyo, mushure mokunge zvimedu zvakakurumidza kutonhora nemhepo yakakura uye zvishoma nezvishoma zvakanyoroveswa nemhepo shoma shoma, zvakaonekwa kuti kuoma kwekare kwakaderera kudarika kwekupedzisira, uye kuputika kwepamusoro kwezvikamu kwakawedzera.Izvo zvakakoshawo kutaura kuti kupwanya zvidimbu zvakakura zvakaoma kuita zvidimbu zvidiki zvinogona kuderedza zvakanyanya kuoma kwezvimedu.

Nguva yekutumira: Mar-14-2024