Mukugadzirwa chaiko kwechikafu, nekuda kwezvikonzero zvakasiyana-siyana, "hari yemidziyo" inogona kuumbwa pakati pemhete inofa uye yekumanikidza roller, zvichikonzera matambudziko akadai sejamming, blockage, uye kutsvedza kwegranulator.

Isu takatora mhedziso dzinotevera kuburikidza nekuongorora kunoshanda uye ruzivo rwesaiti yenyaya:

Isu takatora mhedziso dzinotevera kuburikidza nekuongorora kunoshanda uye ruzivo rwesaiti yenyaya:

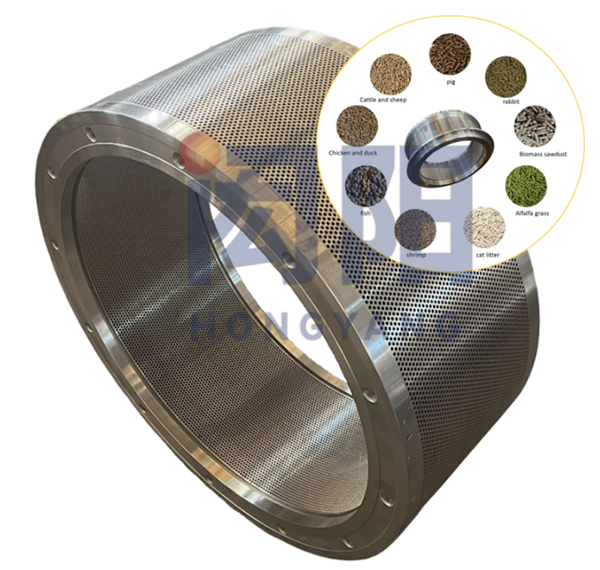

1、Raw zvinhu zvinhu

Zvishandiso zvine starch yakakwira zvinowanzoitika kune steam gelatinization uye ine imwe viscosity, iyo inobatsira kuumba; Zvemidziyo ine yakakwira coarse fibers, huwandu hwegirizi hunoda kuwedzerwa kuderedza kukweshera panguva yegranulation process, izvo zvinobatsira kuti zvinhu zvipfuure nemumhete mold uye inokonzeresa granular inotaridzika zvakanaka.

2 、 Kubviswa kwakashata kwekufa

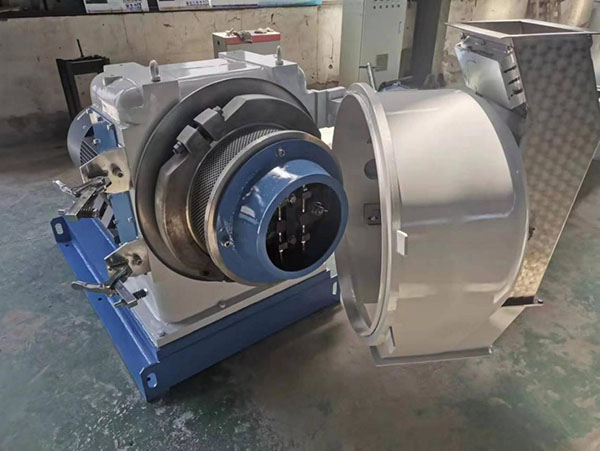

Mukaha uripo pakati pema mold rollers wakakurisa, zvichiita kuti hunyoro hwezvinhu pakati pema mold rollers huve hwakanyanya uye husina kugovaniswa. Iyo yekumanikidza roller inotsvedza nekuda kwesimba risina kuenzana, uye zvinhu zvacho hazvigone kusvinwa, zvichikonzera kuvharika kwemuchina. Kuti uderedze kuvharika kwemuchina, kutarisisa kunofanirwa kubhadharwa kugadzirisa gaka pakati pema mold rollers panguva yekugadzira, kazhinji 3-5mm inosarudzwa.

3, Kukanganisa kwemhando yeutsi

3, Kukanganisa kwemhando yeutsi

Mamiriro akakodzera eiyo granulation maitiro ndeaya: akakodzera hunyoro hwemukati weiyo mbishi, yakanakisa mhando yehutsi, uye yakakwana nguva yekupisa. Kuve nechokwadi chakanaka chemhando yemhando uye yakakwira kubuda, mukuwedzera kune yakajairwa kushanda kweakasiyana ekufambisa zvikamu zvegranulator, mhando yeakaoma saturated steam inopinda muconditioner yegranulator inofanirawo kuvimbiswa.

Hunhu husina kunaka hwehupfu hunokonzeresa kuwanda kwehunyoro hwezvinhu kana uchibuda muconditioner, izvo zvinogona kukonzera kuvharika kwegomba rekuumbwa uye kutsvedza kweiyo pressure roller panguva yekuita granulation, zvichikonzera kuvharika kwemuchina. Kunyanya kuratidzwa mu:

① Kusakwana kwemutsindo wekumanikidza uye hunyoro hwakanyanya hunogona kukonzera kuti zvinhu zvitore mvura yakawandisa. Panguva imwecheteyo, kana kudzvinyirirwa kwakaderera, tembiricha kana zvinhu zvakadzikama zvakare zvakaderera, uye starch haigone gelatinize zvakanaka, zvichikonzera kushata kwegranulation;

② Iyo dzvinyiriro yeutsi haina kugadzikana, ichichinja kubva kumusoro ichidzika, uye mhando yezvinhu haina kugadzikana, zvichikonzera kuchinja kukuru kweiyo granulator, nyota isina kuenzana yemidziyo, uye kuvharika kuri nyore panguva yakajairika kugadzira.

Kuti uderedze huwandu hwemichina kumira kunokonzerwa nemhando yeutsi, vanofambisa fekitori vanofanirwa kutarisisa kune hunyoro hwezvinhu mushure mekupisa chero nguva. Nzira iri nyore yekuona ndeyekutora chitsama chezvinhu kubva kune conditioner woibata mubhora, worega kuenda kunongoiparadzira.

4, Kushandiswa kwemhete nyowani kunofa

4, Kushandiswa kwemhete nyowani kunofa

Kazhinji, kana mhete itsva inotanga kushandiswa, inoda kukuyiwa nezvinhu zvine mafuta, nekuwedzera kwakakodzera kweanosvika 30% yejecha remery, uye pasi kwemaminitsi makumi maviri; Kana pane zvinhu zvakawanda mukamuri yegranulation, uye ikozvino inoderera kana ichienzaniswa nekukuya, inenge yakagadzikana, uye kuchinja kuduku. Panguva ino, muchina unogona kumiswa uye granulation mamiriro anogona kutariswa. Iyo granulation yakafanana uye inosvika pamusoro pe90%. Panguva ino, shandisa zvinhu zvine mafuta kudzvanya mukati uye kutsiva zvinhu zvejecha kudzivirira kuvharika kunotevera.

Kana mold yemhete yakavharwa panguva yekugadzira, mafekitori mazhinji ezvekudya anoshandisa madhiri emagetsi kuburitsa zvinhu, izvo zvinokuvadza kutsetseka kwegomba rekuumbwa uye kukuvadza kune aesthetics yezvikamu.

Imwe nzira inokurudzirwa iri nani ndeyekubika mold yemhete mumafuta, iko kushandisa gango remafuta esimbi, kuisa mafuta enjini, kunyudza mold yakavharika mairi, uye wozopisa nekuipfungaira pasi kusvika paita ruzha, uye woibvisa. Mushure mekutonhodza, kuiswa kwacho kunopedzwa, uye granulator inotangwazve maererano nemaitiro ekushanda. Zvinhu zvinovharira ring mold zvinogona kukurumidza kucheneswa pasina kukuvadza kupera kwechikamu.

Nguva yekutumira: Jul-19-2023