Iyo gap inogadziriswa pakati pekumanikidza roller uye mhete mold ye granulator chikamu chakakosha chekushandisa granulator. Kana iyo gap inogadziriswa inonzwisisika, iyo granulator ichave neyakakwira kuburitsa, yakaderera simba rekushandisa, yakanaka particle mhando, yakaderera kupfeka yekumanikidza roller uye mhete mold, uye hupenyu hurefu hwebasa.

Iyo granulator haigone kushanda nemazvo, iyo yemhando yemhando haina kuvimbiswa, uye kana gaka riri pakati pekumanikidza roller uye mhete mold iri diki zvakanyanya, inopfeka zvakanyanya, uye kunyange kuita kuti mhete yemhete iparare. Izvi zvinoisa kumberi kwepamusoro zvinodiwa kune granulator vanoshanda, vanoda kuve neruzivo rwakapfuma rwekumanikidza roller kugadzirisa. Kuti uderedze kukanganiswa kwezvinhu zvisina kugadzikana zvinokonzerwa nekushanda kwevanhu, uye zvakare kuderedza kusimba kwebasa revanhu uye nekuvandudza kugona kwekugadzira.

Iyo otomatiki inogadziridza tekinoroji yegap pakati pekumanikidza roller uye mhete mold yabuda.

Misimboti yehunyanzvi:

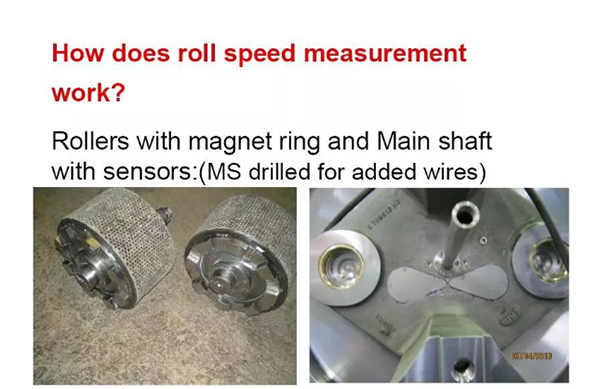

Iyo sisitimu inonyanya kuumbwa neoiri cylinder execution system, angle sensor, uye PLC control system. Basa reiyo oiri cylinder execution system ndeyekusundidzira iyo yekumanikidza roller kuti itenderere wachi kana clockwise, kunyange kana mukaha pakati pekumanikidza roller uye mhete mold inowedzera kana kuderera;

Basa rekona yekona ndeyekunzwa shanduko mukona yekumanikidza roller uye kutumira chiratidzo chekuchinja kune PLC control system; Iyo PLC yekudzora sisitimu ine basa rekushandura shanduko mukona yekumanikidza roller kuita shanduko muhukuru hwegapu pakati pekumanikidza roller nemhete mold, uye nekuienzanisa neyakagadzika kukosha kwekuona kutungamira uye saizi yeoiri cylinder execution system kudzamara iro gap chairo uye gap rakaseti richienderana mukati meiyo inotenderwa huwandu hwekukanganisa.

Technical zvakanakira:

Iyo pa-saiti yekubata sikirini inoshanda seyaipindirana interface, ichiita kuti zvive nyore kushanda;

Deredza simbi kusvika kune simbi kusangana, kuderedza kusakara pane yekumanikidza roller uye mhete mold, kuwedzera zvakanyanya hupenyu hwebasa;

Deredza kudiwa kwemagetsi, kuderedza nguva, uye kuchengetedza nguva nemari;

Kururamisa kwepamusoro, kukanganisa kwegap pakati pekumanikidza roller uye mold yemhete inogona kudzorwa mukati me ± 0.1mm;

Inogona kugadziriswa chero nguva panguva yekushanda kwegranulator, inovandudza zvikuru kuvimbika kwebasa uye kubudirira, uye kuderedza kushanda nesimba;

Hapana mafuta ekuzora, kuwedzera kuchengetedza kwekudya.

Nguva yekutumira: Jul-12-2023