Tsanangudzo yeHongyang feed michina nokudachikafu chehuku nechipfuyo

Chikafu chehuku nechipfuyo chinowanzo reva huku uye chikafu chezvipfuyo, ndicho chikafu chakajairwa muchikamu chekudya.

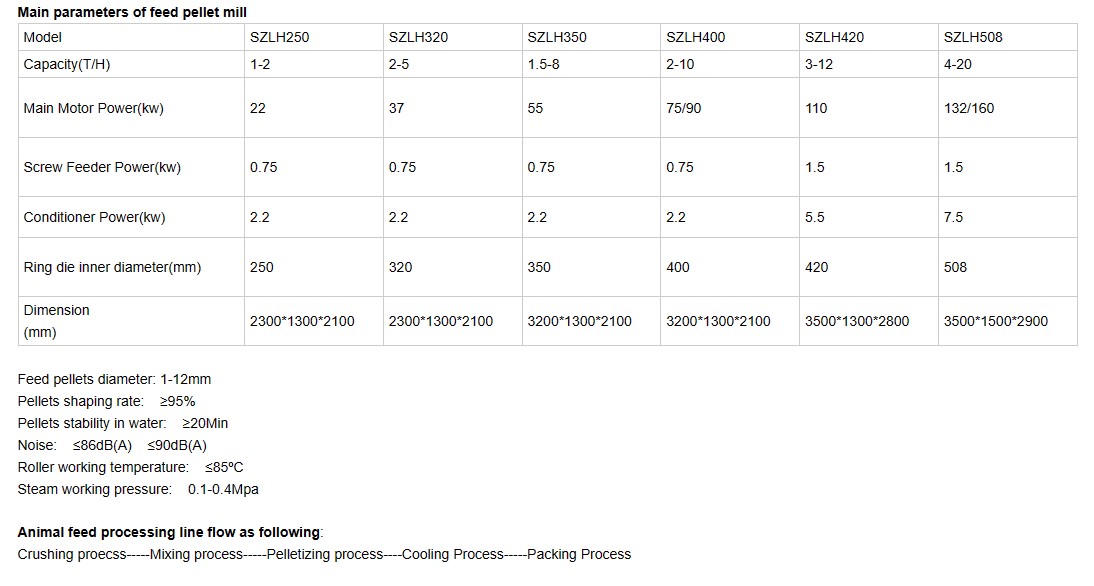

Nhanganyaya yeAutomatic Animal Feed Plant

1. Yakashandiswa zvakanyanya chigadzirwa chine tekinoroji yakakura.

2. Kutyaira kukuru kwehuku feed pellet mill inotora high-precision gear drive, kuitira kuti kubuda kunovandudzwa ne20% kana ichienzaniswa neiyo yebhandi drive.

3. Inotengeswa kunze kwemhando yepamusoro-soro uye chisimbiso chemafuta chinogamuchirwa kuti ive nechokwadi chekushanda, kugadzikana uye kuderera-ruzha rwese muchina kushanda. iyo granulating room ine air suction tembiricha yekudzikisa system.

4. Iyo yekudyisa yepelletizer yekudyisa inotora shanduko-frequency uye inochinja-kumhanya mota kuti ive nechokwadi chemhando yezvimedu zvakaburitswa.

5. Ring inofa nemhando dzakawanda dzemadhayamita akawanda hazvidiwi . uye mhete yemhando yepamusoro inofa inogamuchirwa, kuitira kuti hupenyu hwebasa hurebe. Zvimedu zvakaburitswa zvakatsetseka uye kunaka kwacho kwakakwira .

6. International advanced compensation type yenyoka yakaita sechitubu coupling ine inova uye compact chimiro, kuchengetedzwa kwepamusoro, ruzha rwakaderera uye mwero wakaderera.

7. Plus-saizi conditioner uye jekete type conditioner yehuku feed pellet mill zvinosarudzwa kusimbisa particle conditioning effect.

Raw Materials for Feed Pelletizing

Mapeteti echikafu anowanzo gadzirwa nechibage, mupunga webrown, paddy, mhunga nehupfu hwesoya.

Material Kuchenesa Sieving uye Kugamuchira Maitiro

Nekugamuchira zvinhu, chirimwa chedu chinoshandisa granule yekuchenesa uye yeupfu yekuchenesa kuchenesa guruva uye mamwe marara, ipapo magineti silinda inochenesa masimbi nesimbi mumidziyo. Mushure mekucheneswa, zvinhu zvinotumirwa kune inotevera nzira.

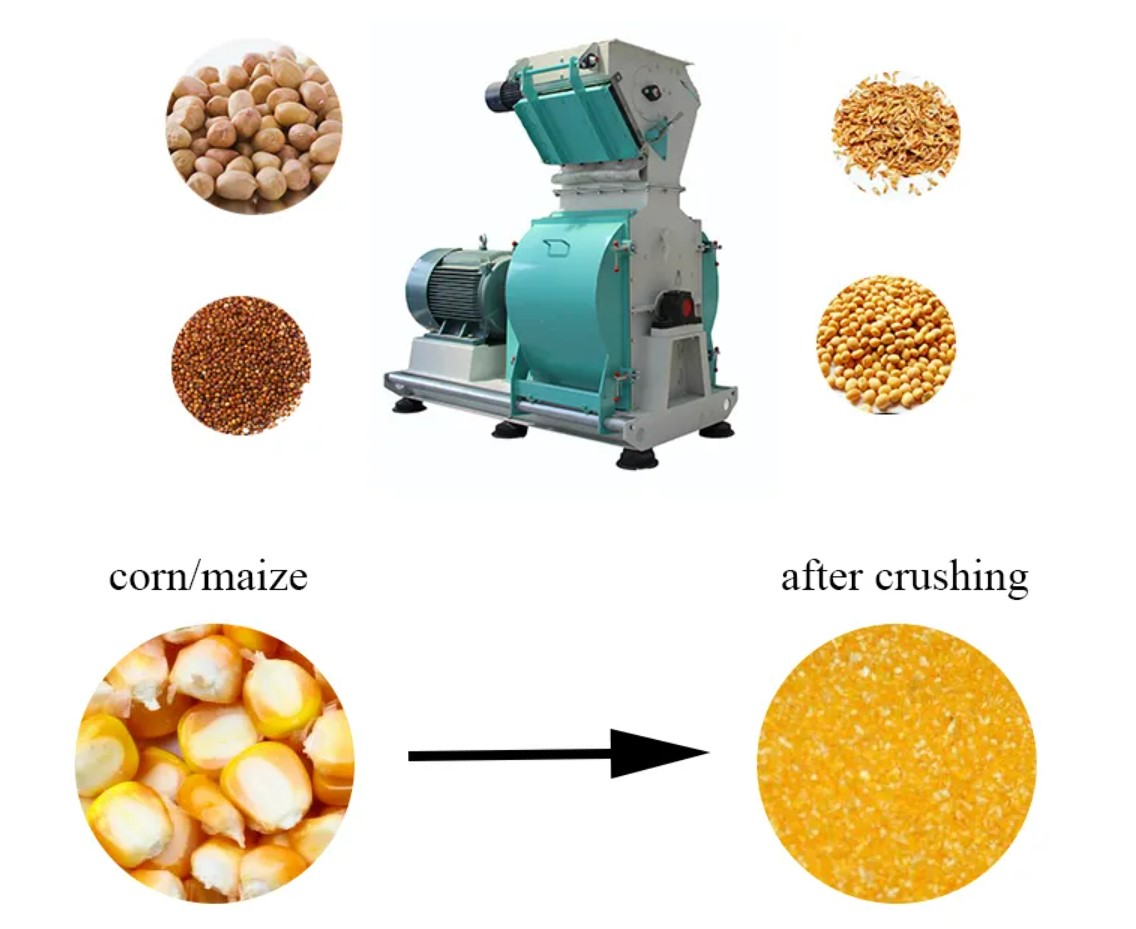

Raw Material Kukuya Maitiro

-General-chinangwa zvigadzirwa, yakagadzikana kuita, inoshandiswa zvakanyanya muhombe uye yepakati-saizi chikafu, chikafu chekugadzira mabhizinesi ezvigadzirwa zvakapwanyika.

-Muchina uyu unoshandisa dhiraivha yakananga, sainzi uye inonzwisisika sando kurongeka, sando sieve clearance, yakapedza fineness yunifomu. Kupwanya kamuri yechipiri kurova tekinoroji. Kusarudzwa kwemabhengi emhando yepamusoro, yakaderera tembiricha yekushanda.

-Yakasiyana-siyana yescreen size yakasarudzika, inokurumidza kuvhurika gonhi mechanika uye elastic kudzvanywa screen masisitimu, yekukurumidza skrini, kushanda kuri nyore uye kugadzirisa.

-Gamuchira mhando yemhando yepamusoro inotengeswa kunze kwenyika, tungsten carbide alloy spray sando. Bearing tembiricha kuratidza chiridzwa.

Feed Material Auto Batching uye Kusanganisa Maitiro

-Dosing/Batching dhizaini magadzirirwo zvinoenderana nezvinovaka muviri zvinodiwa zvemhuka dzakasiyana, uchishandisa chaiyo mudziyo kuyera nemazvo zvakasiyana-siyana zvinongedzo. Kusanganisa iko kuvhiya uko kwakasiyana siyana kwekudya kunosanganiswa uye kusanganiswa pasi pemasimba ekunze kuti aumbe yunifomu kugovera. Iyi maitiro anotora maviri batching chiyero uye akati wandei mabhenji mabhini, ayo madiki emukati anowedzerwa nemaoko ane cheki weigher. Mushure mekunge batching yemidziyo yemidziyo yapera, wobva wapinda musanganisi wekusanganisa, uye pakupedzisira zvinhu zvacho zvinobuda kuburikidza nemutakuri uye lifti.

-Weresa midziyo: batching chikero, batching kururama≤3‰.

-Kusanganisa midziyo: musanganiswa SHSJ4, 30KW, 2000kg pabatch, huwandu 20-30T/H.

-Kusanganisa kumhanya ipfupi, kusanganisa kutenderera kupfupi, 30-120 masekonzi / batch; kusanganisa kufanana kwakakwirira, CV ≤ 5%, uye haibereki kupatsanurwa;

-Muchina wekusanganisa maitiro ari pakati nepakati, kurodha akasiyana siyana;

-Inotarisirwa kusangana nezvinodiwa zvezvakatipoteredza; inogona kuve yakashongedzerwa neyakaomeswa mweya yekuchenesa system, iyo yakasara kune yakaderera mwero;

-Inogona kugadzirwa yakakosha atomization spray system; wedzera molasses, Girisi uye mamwe mayunifomu;

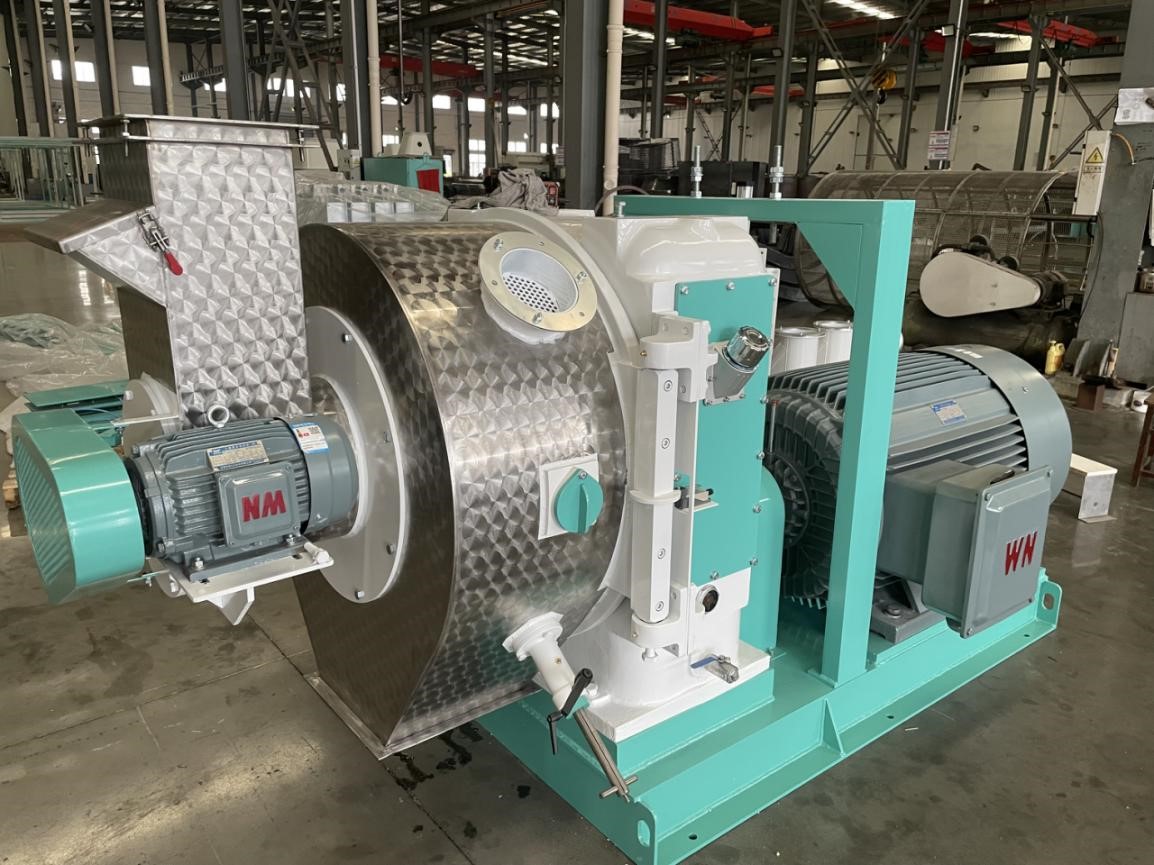

Feed Pelletizing Process

-Yakagadzirwa kubva kuCPM modhi, Europe uye United States bhokisi.

-Iyo huru dhiraivha inoshandisa yakakwirira chaiyo giya dhiraivha, iyo inobuda inenge 20% yakakwira kupfuura iyo bhandi drive mhando.

-Kusarudzwa kwemabhengi emhando yepamusoro-soro, zvisimbiso zvemafuta, kuve nechokwadi chekuti muchina unoshanda zvakanaka, wakagadzikana, wakaderera ruzha.

-Feeder yakagadzirwa nesimbi isina tsvina, nekushandisa frequency control mota kuona kuti mhando yezvimedu zvinoburitswa.

-Single Conditioner kana maviri maconditioner anogona kusarudzwa, akagadzirwa nesimbi isina tsvina, kuti afanobika mbishi zvinhu zvisati zvaita pelletizing.

-Iyo yepasirese yepamusoro nhanho yekuripira rudzi rwenyoka chitubu chekubatanidza, ine chimiro chitsva, compact, yakachengeteka, yakaderera ruzha, yakaderera kukanganisa kuita.

-Ring mold yekusimudza mudziyo, giya bhokisi giya otomatiki kutonhora system.

Dyisa Pellet Kutonhora uye Kuputsika Maitiro

Dyisa Pellet Kutonhora maitiro

-Iyo yazvino octagonal inotonhorera dhizaini dhizaini, hapana inotonhorera yakafa magumo. Iko kushandiswa kweiyo yakavharwa feeder feed, munzvimbo yemhepo, kutonhora mhedzisiro kwakakosha.

-Kuburitsa zvinhu zvakaenzana uye zvakaenzana zvakarongedzerwa mukabhini.

-Kushandiswa kwema slide valve reciprocating discharge mechanism, kufamba kwakatsetseka, kwakavimbika, kune zviduku zviduku.

-Low simba kushandiswa, nyore kushanda.

-Mushure mekutonhodza tembiricha yapera yechigadzirwa haina kukwira kupfuura tembiricha yekamuri +3 ºC ~ 5 ºC, inokodzera kutonhodzwa kwezvinhu zvegranular.

Kudyisa Pellet Crumbling process

Diameter ye feed pellet inogona kugadziridzwa neyakasiyana die mold gomba, asi kureba kunogona zvakare kugadziriswa nemuchina wekudya pellet crumbler muchina. Roller mhando feed pellet crumbler ndiyo yakanakira midziyo yekudyisa pellet kupwanya. Kaviri-roller feed pellet crumbler yakakodzera kupwanya feed pellet, senge chikafu chehuku, chikafu chedhadha uye goose feed, nezvimwe.

Dyisa Pellet Kuongorora uye Magiredhi Maitiro

-Musanganiswa wedenderedzwa, oval, akatwasuka matatu marudzi ekufamba, kuongorora maitiro akanaka. Screen ship drive ine bhandi dhiraivha, kusimbisa pachiyero, yakaderera ruzha.

-Screen muswe rutsigiro kune yakagadziridzwa elastic rutsigiro, vibration, yakaderera ruzha. Simbisa hwaro kuti uve nechokwadi chekushanda kwakadzikama kwemidziyo.

Kudyisa Pellet Packing Process

-Yakakwirira-chaiyo kuyera chiratidzo, yekunze PLC, yakakwirira-chaiyo analog mutoro sero inoumbwa neyekuyera kutonga system.

-Inoshanda kune zvinhu zvisina kufamba zvakanaka. Muchiyereso chekuyeresa, hopper pane sisitimu ine chiteshi chekukweva, inogona kunyatso kudzora kupera kweguruva remidziyo kuona kuti guruva renzvimbo munzvimbo yekushanda, uye rinogona kuita chiyero chekumanikidza kwemuviri kuchengetedza kuenzana nenyika yekunze, kudzivirira kuyerera kwemhepo kunoyera kurongeka.

-Kurongedza kurongeka: 0.1% Packing range: 5-50kg / bhegi

Otomatiki PLC Kudzora System

Iine otomatiki PLC yekudzora sisitimu, mutsara wekudya wemhuka une hunyanzvi hwekuita uye kushanda kuri nyore.

1. Yakazara otomatiki yemutsetse wakakwana wekugadzira

2. Kugara kwechigadzirwa chemhando pamwero wepamusoro

3. Lower manpower zvinodiwa, shoma nguva mutengo

4. Kutariswa kuri nani kwemaitiro ekugadzira

Nguva yekutumira: Nov-22-2023