Stainless Simbi Mhete Inofa - Durable Replacement Parts for Feed Pellet Mills

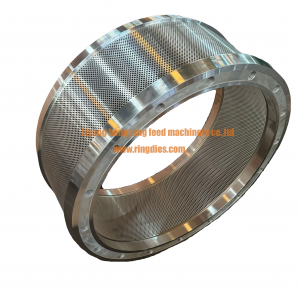

Pellet chigayoring kufas chinhu chakakosha mukugadzirwa kwemhando yepamusoro yekudya kwemhuka, matanda emapuranga ekudziya, uye mamwe maindasitiri ekushandisa. Idzi dzinofa dzinowanzo gadzirwa kubva kune yakakwirira-yakasimba uye yakasimba zvinhu, senge kabhoni simbi kana Stainless simbi, uye dzakagadzirirwa kutsungirira kumanikidzwa kwakanyanya uye kupisa kunogadzirwa panguva yepelletization process.

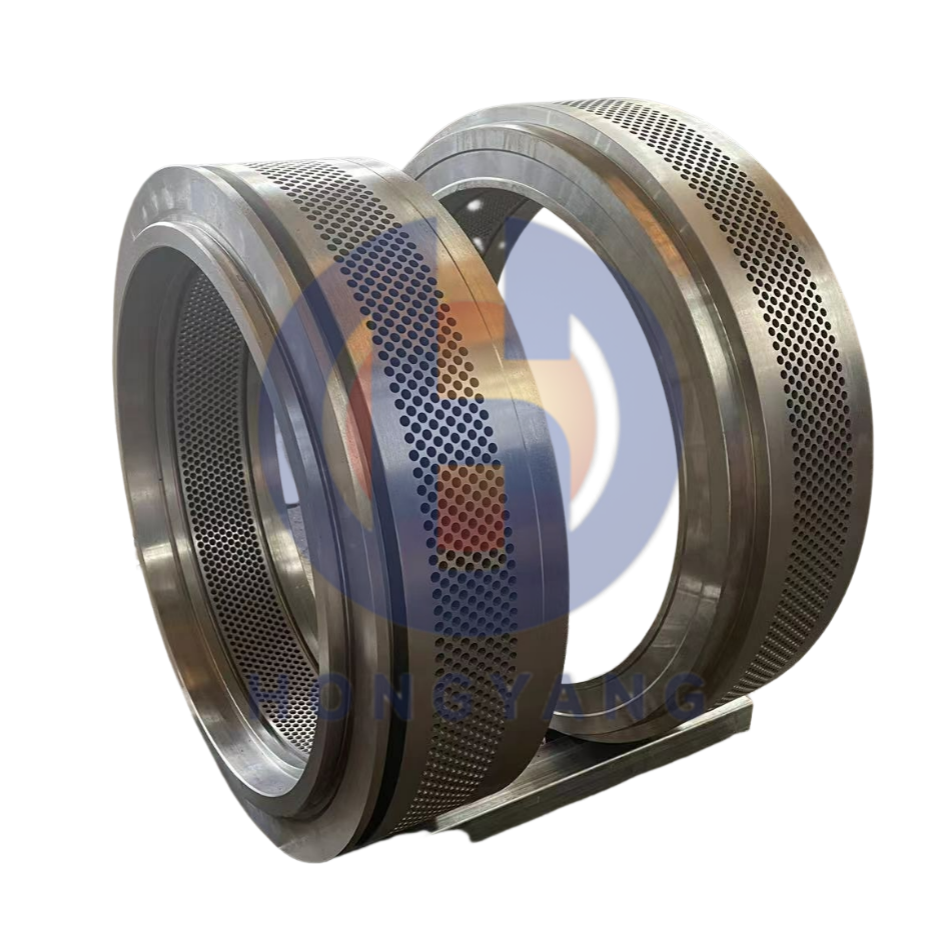

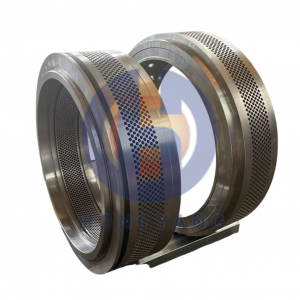

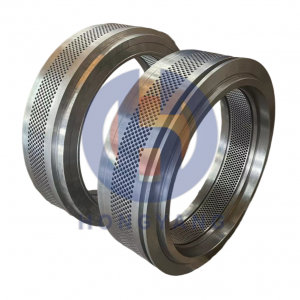

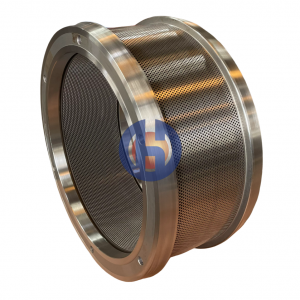

Dhizaini yechigayo chepelletring kufakwakakoshawo kuti uve nechokwadi chekuenderana uye kugadzirwa kwepellets. Maburi kana machani ari mumhete anofa akanyatsogadzirwa kuti ave nechokwadi chekuti feedstock yakatsikirirwa uye kuumbwa kuita mapellets ehukuru hwakati uye density. Yakagadzirwa nemazvo uye yakachengetedzwa mhete inofa inogona kuvandudza zvakanyanya kunaka uye kugona kwekugadzirwa kwepellet, kuderedza marara uye kuwedzera purofiti.

Pellet mill mhete inofa inouya muhukuru hwakasiyana-siyana uye mapatani egomba kuti agare akasiyana marudzi ezvipfuyo uye saizi yepellet. Mhete yedu inofa inogadzirwa pachishandiswa tekinoroji yepamusoro uye zvemhando yepamusoro zvinhu kuti ive nechokwadi chekushanda kwakakwana uye hupenyu hurefu. Izvo zvakagadzirirwa kuve nyore kuisa nekuchengetedza, uye isu tinopa huwandu hwakasiyana hwekutsiva zvikamu uye zvishongedzo kuchengetedza pellet yako chigayo chichifamba zvakanaka.

Kuisa mari mumhando yepamusoro pellet mill ring inofa haingogadzirise kunaka uye kuenderana kwemapellets ako asi zvakare inowedzera kushanda kwese uye pundutso yekushanda kwako.